Streamlining Optical Medical Device Development, Validation, and Manufacturing

Practical Precision specializes in the development of complex, highly integrated optical medical devices and optical subsystems for startup and established medical device companies, often as an expert partner to a client with its own deep focus or to a more broadly focused medical device development company.

This exclusive focus has allowed us to develop highly-relevant experience and deep expertise solving optical device engineering challenges within the regulatory constraints and market demands of the medical device industry. Coupled with our advanced analysis, modeling, prototyping, and testing techniques, this helps our client companies to:

- Realize and enhance the value of their technology, device, and company at every stage of development, preserving and securing capital along the way.

- Deliver a safe, effective device that provides the best possible experience and outcomes for patients and providers alike.

- Streamline the transfer of complex optical medical devices from engineering labs to a scalable manufacturing process.

Our consulting relationships begin with a free, 30-minute Discovery Call. It’s a high level discussion that doesn’t involve any confidential or proprietary information.

Imagination, Expertise, Execution

Optical Medical Devices and Instruments

- Development of Class II and Class III medical devices incorporating optics, lasers, and/or motion for diagnosis and treatment, including:

- Camera system and stereo viewer for surgical robot, closing the loop between surgeon and instrument.

- Surgical laser system with real time feedback and precision guidance.

- Dermatological laser system with ergonomic handpiece incorporating 3D scanning mechanism.

- Handheld in vivo cellular imaging system.

- Visible, infrared, and fluorescence imaging and microscopy systems for diagnosis; automation and optimization of treatment; and post treatment assessment.

- Fluorescence microscopy, spectroscopy, and optical coherence tomography (OCT) instruments.

- Diagnostic and therapeutic laser systems.

- Design of optical benches involving multiple sources, detectors, and sensors; active and passive optical components; multiple imaging and laser paths; and combined optical paths.

- Design of optical medical devices to withstand sterilization by methods including ETO and autoclave, protecting sensitive and precision aligned components

Medical Laser Systems & Devices

- Design of therapeutic and diagnostic laser systems using a wide range of class 1-4 laser technologies, including fiber, diode, solid state, gas, and dye lasers for dental, surgical, dermatological, and cosmetic procedures

- Design, build, alignment, calibration, and testing of complete beam delivery systems, including optical benches/sources; articulated arm or fiber-based couplers; and ergonomic handpieces, robotic end effectors, and scanning outputs.

- Design of compact, highly integrated devices that incorporate co-aligned laser and imaging components for monitoring and control of treatment and advanced diagnostics.

- Implementation of laser safety measures in the device and process to protect patient and provider as well as development and manufacturing teams.

Handheld Devices, Handpieces, and End Effectors

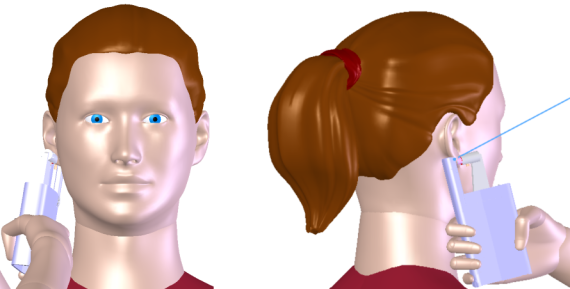

- Compact, highly integrated devices, handpieces, and end effectors incorporating co-aligned laser and imaging components; scanning and focus mechanisms; and patient interfaces that optionally manipulate or stabilize tissue.

- Ergonomic and stable patient and provider interfaces that enable controlled and effective treatment and diagnosis.

- Coordinated motion and tissue manipulation, e.g., focusing and scanning a laser while squeezing then relaxing the tissue in a controlled fashion.

- Internal focus and linear/rotary scanning mechanisms using a variety of technologies.

- Integrated misting and cooling systems utilizing air, water, and/or TECs.

- Precision feedback and guidance using integrated cameras; illumination and pointers; and/or IMUs.

- Design for autoclave by leveraging modularity; autoclave-rated components and materials; and our experience designing for harsh industrial and defense environments.

- Designed to withstand shock and vibration during, shipping, handling, and use by utilizing advanced packaging and optical mounting techniques as well as advanced simulation and testing.

Proving Novel Technologies, Producing Viable Products

Optical medical devices use light to detect, diagnose, or treat disease or injury. Often, these devices also involve coordinated motion – focusing or scanning the light, for example, while squeezing or stretching tissue. The safety, efficacy, and reliability of these devices requires specialized and careful design, construction, and alignment. Ergonomic and clinical considerations that constrain the size and shape of the device can further complicate the design and manufacturing process.

There are many hurdles on the way from concept to commercially successful medical device. They can be either milestone achievements that add value to the device and the enterprise (often in the form of investment that allows continued development) or stumbling blocks. The same experience and expertise with medical optical systems that is vital to the safety and efficacy of the device is also vital to the success of the product development effort as a whole:

- Early on, speed of development is critical as the basic science and technology are proven out and refined. But even then, fragile or unstable test devices can delay progress and confuse results.

- As more prototypes are developed and tested, stability and consistency from unit-to-unit becomes more important. Also, design decisions made at this time are increasingly difficult to change later and have a more significant impact on the viability of the eventual device.

- Most of these innovative and sensitive devices will require clinical trials for validation, which will hinge on the stability and reliability of the optics and mechanisms when exposed to shipping and handling; a less controlled environment; and extended use for the first time.

- In production, an optical medical device that was not designed with alignment, fixturing, and tooling in mind will be difficult for non-specialists to build, align, and test. The device will have already been through verification and validation, so only marginal improvements can be made using external tooling and fixtures without invalidating the design. Yield may suffer and it will be difficult to scale production.

With focused expertise in developing optical systems for volume production and highly relevant experience applying it to a wide array of medical devices, Practical Precision can help you streamline this process and develop a successful product that can both create and meet growing demand.

Our consulting relationships begin with a free, 30-minute Discovery Call. It’s a high level discussion that doesn’t involve any confidential or proprietary information.