Engineering High-Performance Digital Prepress, Printing and Finishing Systems

Your customers value output quality, throughput, and total cost of ownership.

But these performance specifications are often at odds with one another:

- Increased throughput requires faster moves, which degrades accuracy and quality.

- Chasing higher fidelity leads to over-specifying and replacing the current weak link with more expensive components, more rigid and heavier plates, beams, and frames.

- The increased weight makes the system more difficult to accurately control and requires larger, more expensive drives and drive train components.

Real, cost-effective gains aren’t made by replacing the weak link. It requires fixing the chain.

Breakthrough profit and performance is achieved with a systematic, engineered solution.

Contributing to Your Success, By Doing What We Do Best

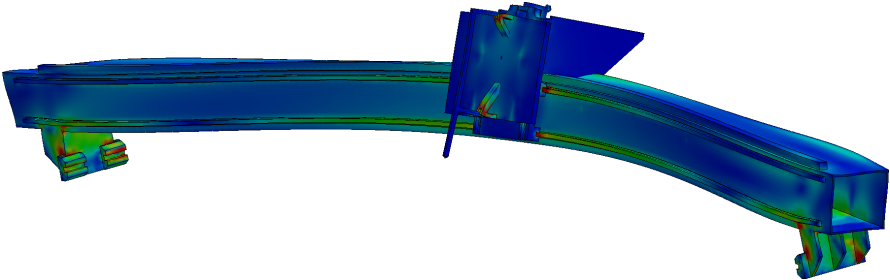

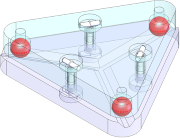

Practical Precision specializes in the engineering, analysis, and optimization of precision motions systems for digital printing and finishing.

We develop beams and gantries, material handling systems, and complete systems for commercial scanners, printers, cutters, and direct-to-garment printers, from grand format to kiosk size.

We understand the different demands and challenges posed by the smooth motion of a printer and the rapid changes in speed and direction of a cutter.

Contact Practical Precision at 866-895-7146 x. 101 or rob@practicalprecision.com to discuss how we can help you:

- Develop a new system with a robust design that achieves your performance objectives and serves as a strong platform for future increased performance and capabilities that set the standard in your market.

- Review an existing system to develop a systematic strategy to upgrade its accuracy, throughput, or total cost of ownership and lay the groundwork for future improvements and optimizations.

- Rescue an existing development or upgrade that is failing to meet performance specifications.

We look forward to the opportunity to help make your product a success.

Sincerely,

Rob Campbell, PE