A glossary of terms, concepts, and metaphors used in the disciplines of precision engineering, precision machine design, and optomechanical engineering.

Each term is defined briefly below. The link for each terms includes extended definitions, explanatory images, and a list of articles in which the term is further explained or used as a key concept.

The maximum deviation from an ideal outcome (e.g., moving to an exact position, exactly measuring a quantity, bonding a stack of pre-aligned wafers without disturbing the alignment) and the actual outcome. The lower limit of accuracy is repeatability.

A measure of the fractional change in size of an object per degree change in temperature at constant pressure. Symbol: α or CTE. Units: 10-6/K [10-6/°F]

The relative change in size between components with different coefficients of thermal expansion that are undergoing the same change in temperature.

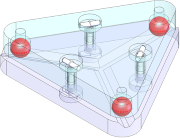

A form of wear caused by adhesion between sliding surfaces. Materials that form a thin layer of hard oxides with high coefficients of friction, such as aluminum and stainless-steel, are especially prone to galling. In precision engineering, galling is a particular concern when contact stresses are high, such as in kinematic mounts.

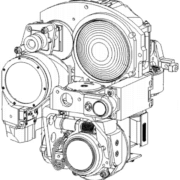

The discipline of designing a machine or instrument so it can maintain, measure, or move to a position or follow a path with a level of accuracy that is many orders of magnitude smaller than the size of the machine or instrument itself. Also, the body of knowledge, wisdom, and techniques that is used to design such a machine.

The variation in a result over many attempts to produce the same outcome, under the same conditions (e.g., moving to the same position, taking the same measurement, or bonding successive stacks of wafers). Repeatability is the lower limit of accuracy.

The smallest increment of measurement, movement, or other output that a machine, instrument, or component is capable of.

The deflection of a structure due to the effect of gravity acting on its mass. It can be one of the most significant sources of error in optical systems, affecting both the relative alignment of optical elements and the form of individual optical surfaces.

A measure of thermal expansion for a given steady-state thermal load equal to the coefficient of thermal expansion over the thermal conductivity, α / k. Units: μm/W.

A measure of how quickly a material transfers heat across a temperature difference. High thermal diffusivity can minimize the development of thermal gradients by allowing a part or parts to reach a uniform temperature quickly. D = thermal conductivity / (density x specific heat capacity) = k / (ρ x Cp). Units: m2/s [in2/s].

transient distortion coefficient – A measure of the “time for a thermal distortion to dissipate per unit of temperature gradient”, equal to the , α, over the , D. It has units of s/(m2∙K). Material properties and thermal properties in particular tend to vary with temperature. As a derived property of two thermal properties, the […]