A practical guide to kinematic mount design for custom, real world applications: from theory, to design and analysis, to CAD modeling, to production.

Precision Engineering Articles

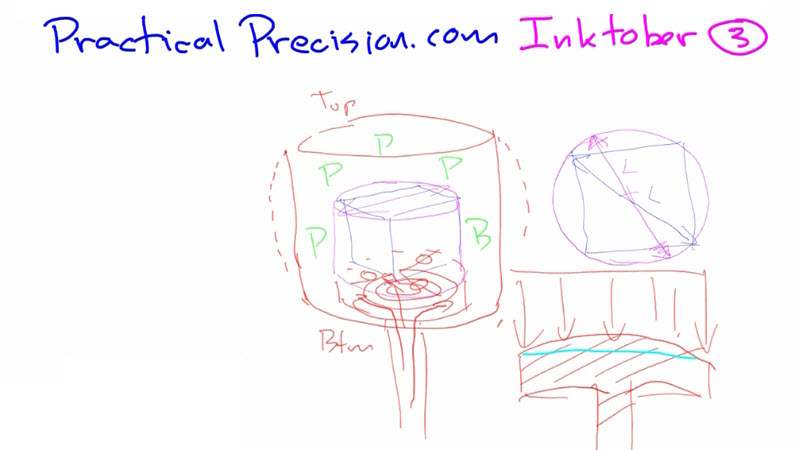

#inktober #engineering Day 3 – Product and machine footprint

We look at how the raw material, processing, and final form of the product produced by the system influences the basic layout of the system. “Round” has lots of benefits, including volumetric efficiency and rotational symmetry, but the way the material is processed suggests a different footprint for this application.

#inktober #engineering Day 2 – Designing from the product out

Continuing on from day 1 of the #inktober #engineering challenge, we refine the performance requirements of our metal additive manufacturing system in terms of: The business benefit that it provides to the end user - our customer's customer The output of the system -...

#inktober #engineering Day 1 – Introduction

#inktober is a 31 day challenge created by cartoonist Jake Parker to encourage artists to develop both their drawing skills and positive drawing habits by doing one ink drawing per day for the entire month. I'm bringing inktober to engineering to encourage development...

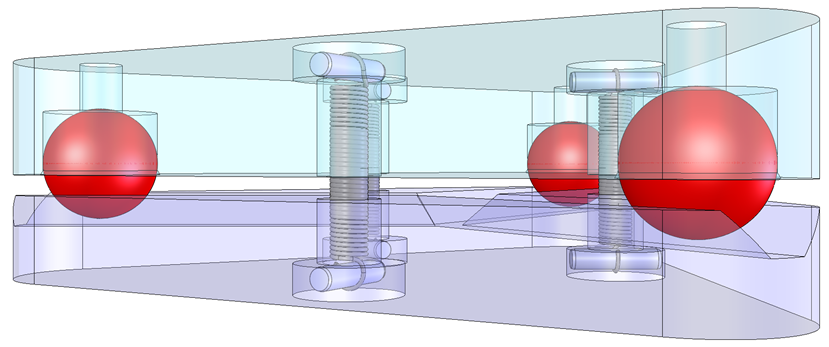

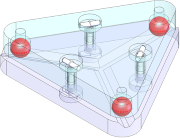

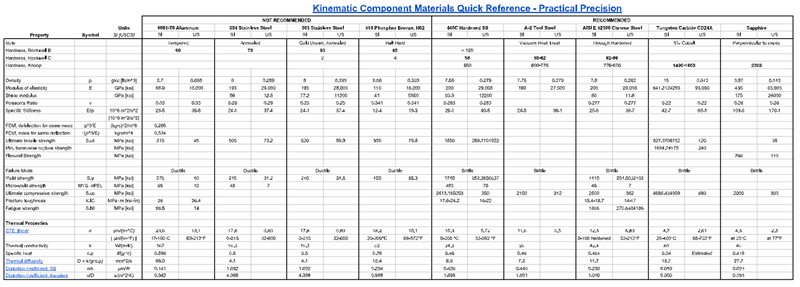

Selecting Materials for Kinematic Components

Kinematic components are the set of balls, vees, and other shapes that come into point contact with each other to locate the structural members of a kinematic mount relative to one another. In this article, we discuss the desirable material properties of kinematic...

What Is Precision Engineering?

What is precision engineering? What fundamental difference sets it apart from “traditional” mechanical engineering, and how can that understanding help make your precision design a success?