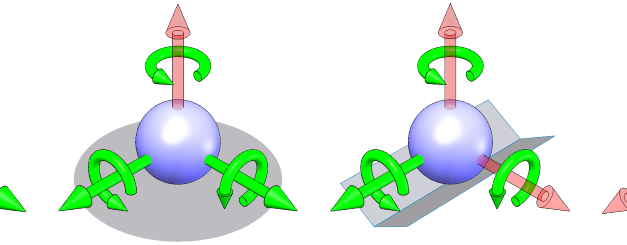

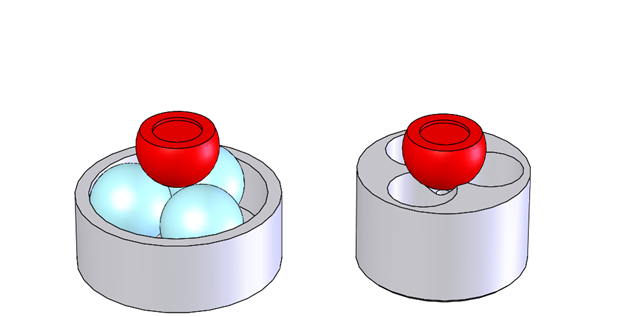

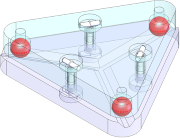

The Principle of Kinematic Constraint

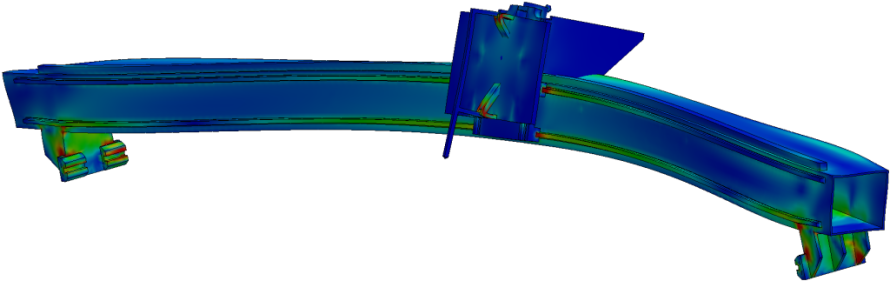

The advantage of a kinematic mount is that it locates one rigid body relative to another with very high repeatability, without over-constraining the body or introducing instability. It accomplishes this by using the precise number (and arrangement) of contact points needed to allow the desired degrees of freedom – no more and no less. That is the principle of kinematic constraint, which this article will show how to apply in your designs.

Read More